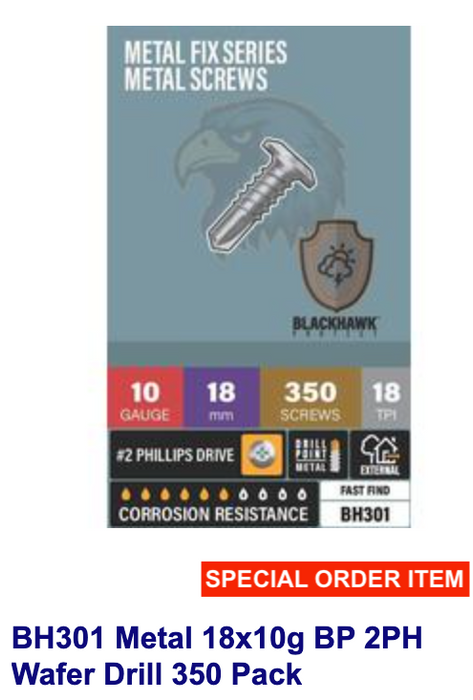

Screws for For Modwood KlevaKlip Metal Joist BH301 Box of 350

| BH301 Metal 18x10g BP 2PH Wafer Drill 350 Pack for Modwood KlevaKlip Metal Joist Covers 9m2 - Covers 9m2 at 450 Joist Centres |

SPECIAL ORDER ITEM - 3 to 4 Days Lead time

Blackhawk Fasteners Metal Fix screws

BSM018X010BP2PHD350

Blackhawk 10 gauge, drill point, wafer head, Blackhawk Protect, Phillips drive screw

Screws come in a range of sizes and materials. Choosing the wrong screw can add unnecessary time and cost to your project. The Blackhawk Metal Fix screws have a range of features that will help get the best finish for your project.

Blackhawk Protect

The screw material is one of the most import factors when making your purchasing decision. Getting this wrong can have a huge impact on the strength and durability of your project. Blackhawk Metal Fix screws are made with the Blackhawk Protect coating. Blackhawk Protect is a high-grade, tri-layer coating process. These layers are joined together through a chemical process which results in a tightly bonded coating on the screw. Along with conforming to AS 3566.2 Class 3, Blackhawk Protect has advantages like:

- Superior corrosion (rust) resistance over non coated/galvanised fasteners

- The unique layering process reduces any damage to the coating if the screw is scratched

- Less risk of premature corrosion due to reactions with other metal types

Blackhawk Protect is environmentally friendly and does not contain hazardous substances like lead, cadmium, mercury or hexavalent and trivalent chromium. Blackhawk Protect, like all class 3 equivalents, is not recommended for applications within 5km of breaking surf or in close proximity to swimming pools.

There are a number of environmental factors that can contribute to premature corrosion of fasteners. These factors can be, but are not limited to the following:

- Salt water and salty air carried from a salt water body

- Preservative treated wood

- Soils

- Poor quality decking oil or decking paint

It is recommended that you discuss this with your builder or local council prior to commencing work.

Size

The Blackhawk Metal Fix screws are available in a length of 18mm.

- Gauge = the diameter of the threads (10 gauge = 4.50mm).

- Length = the measurement from the underside of the head to the tip of the point.

Drill Point - Metal

Drill point refers to the sharp, drill like point at the end of the screw. The drill point drills a hole through light gauge metal. The thread of the screw then creates a thread in the metal, gripping the screw and helping it drive into place.

#2 Phillips Drive

The Phillips drive consists of two recessed cuts in the shape of a plus “+”. It was originally designed so the screw could not be over-tightened. It is now one of the most common drive types used in fastening. “#2” refers to the size of the recessed cuts in the head of the screw. The larger the number, the larger the cut size.

Wafer Head

The wafer head is a broad, low-profile head with a flat, bevelled top and flat underside. The wafer head is designed to sit flat on the surface being fixed. The broad head acts like a washer and helps in fixing two pieces together.

KlevaKlip®

The Blackhawk Timber Fix screws were specially designed for use with the KlevaKlip® Snap-LOC decking clip when fixing ModWood composite decking boards. The low-profile head ensures the decking board engages with the decking clip. You can find more information on ModWood on the ITI Australia website https://itiaustralia.com.au/modwood/